The last process in PCB production is to separate the boards from the production panel, and this is usually done by V-scoring or tab-routing. V-scoring, V-cut, or V-groove is one of the most common panelization methods. In V-scoring, the top and bottom of the panel are V-shaped grooved, leaving only a thin layer of material in between. This ridge enables one to easily snap the individual boards apart when needed.

When talking of V-scoring, jump scoring is worth mentioning. This is a specialized technique where the cutting blade "jumps" over certain areas of the panel instead of cutting the entire length. It does, however, require very accurate V-scoring equipment and well-programmed settings in order to produce high-quality final boards.

Why V-score PCB panels?

V-score panels are extremely popular when it comes to PCB manufacturing and assembly because they enable the simple separation of the finished boards in a quick and efficient way. The process further reduces material wastage and production cost, hence being cost-efficient. V-cut panels also do not require a frame border for mechanical integrity.

Because of these benefits, V-scoring is being used extensively in both low-volume prototype assembly and high-volume PCB fabrication to enhance the efficiency of manufacturing. That said, V-scoring is ideally applicable to boards that are square or rectangular and equal in size because the blade must travel over the entire panel in straight lines continuously without interruption. When the design calls for irregular shapes, tab routing is the option, though more complicated and costly.

Design rules for V-scoring use

The V-scoring lines must be straight and run the entire length of the panel—there can be no breaks.

The total panel size has to be within 75mm * 75mm and 450mm *1245mm.

There can be zero spacing between sub-boards; the V-cut line defines the board outline.

The breakaway rail (from the V-cut line to the panel edge) has to be at least 5.0mm.

The standard V-scoring angle is 30°.

V-scoring is recommended for boards thicker than 0.6mm; for thinner boards, single-sided V-scoring is preferable.

Keep tall components or large solder areas away from the V-cut line to avoid separation damage.

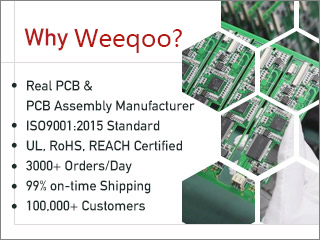

Why Weeqoo

Weeqoo provides precise and reliable V-scoring technology, along with a range of other high-quality panelization solutions. With our state-of-the-art equipment and experienced engineers, your PCB manufacturing needs are met to the very highest levels.

If you have any PCB projects in mind, feel free to reach out to us — our professional team is ready to offer the most suitable and efficient solution for you.