What Is a Laser Stencil?

A laser stencil is a key tool used in PCB assembly to apply solder paste during the surface-mount process accurately. Based on different manufacturing methods, stencils are divided into three types: laser-cut, chemical-etched, and electroformed. Among them, laser stencils, typically made from thin stainless steel sheets, offer the highest precision and consistency.

When ordering a stencil, you can choose between framed (with framework) and non-framed options.

Framework stencils are suitable for automated and semi-automated stencil printers and come in several standard sizes.

Non-framework stencils are usually used for manual soldering and can be customized according to your project requirements.

The Function of a Laser Stencil

In surface-mount technology (SMT), a laser stencil plays an essential role in ensuring precise solder paste application. Each stencil is laser-cut to form apertures that match the component pads on a specific PCB design. Once the stencil is aligned and fixed on the PCB, solder paste is spread across its openings to create solder pads. Afterward, components are mounted through pick-and-place and reflow soldering processes.

Because every stencil corresponds to a specific circuit layout, it’s typically used for one design only. Therefore, PCB manufacturers usually include the stencil cost in the overall quotation — though in some cases, it may be provided free of charge.

Why Weeqoo Provides Laser Stencils for Customers

When placing a PCB order on Weeqoo’s website, you can conveniently add an SMD stencil to your order. Weeqoo offers multiple stencil sizes, including both framed and non-framed options. The largest stencil size available is 500mm × 1400mm, with a valid printing area of 320mm × 1200mm.

The accuracy of a stencil has a direct impact on the quality and efficiency of PCB assembly. That’s why Weeqoo strongly recommends laser stencils for both prototype assembly and mass production. Laser-cut stencils are more precise, easier to handle, and significantly reduce production time. Customers can also choose between electropolished and non-electropolished finishes — with electropolishing offering smoother apertures and improved solder paste release.

Importance of Laser Stencils in Modern PCB Assembly

With the rapid advancement of electronics, PCBs and components are becoming increasingly compact and high-density. This trend raises the requirements for PCB manufacturing accuracy and the performance of supporting tools. High-quality laser stencils ensure cleaner solder application, fewer defects, and higher assembly yields — making them an indispensable part of modern production.

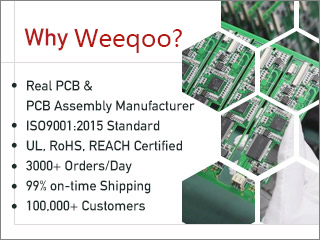

At Weeqoo, we provide one-stop PCB services, including PCB prototyping, component sourcing, PCB assembly, and testing. Our laser stencil solutions are designed to support your projects from prototype to full-scale production with unmatched precision and reliability.

If you’re looking for a professional PCB manufacturer offering high-quality laser stencils and complete PCB assembly services, Weeqoo is your trusted partner.