PCB edge plating is a process that connects the top and bottom layers of a PCB by electroplating the outer edges. It’s also known as side plating, border plating, edge metallization, or plated contour. For devices that require strong EMC performance, signal integrity, or heat dissipation, edge plating offers clear advantages at a very low additional cost. Typically, ENIG or nickel-gold surface finishes are recommended for this process.

Comparison Between PCBs With and Without Edge Plating

Benefits of PCB Edge Plating

Prevents electromagnetic radiation from leaking through the board edges.

Enhances EMC performance.

Provides better signal integrity.

Helps with heat dissipation.

Supports board-to-board and housing connections.

Strengthens edge connections and offers mechanical protection.

Improves soldering results along plated edges.

Increases the PCB’s current-carrying capability.

Key Design Considerations for Edge Plating

In the CAD layout, use overlapping copper to define the plated area—minimum overlap should be 500 μm.

Ensure strong adhesion between layers by keeping the edge surface smooth and selecting proper plating materials.

Minimize burrs during processing.

Avoid placing metallization on small bridge locations.

Do not extend internal power planes to the board edge.

Reserve enough space on the edges for plating.

Define the board outline requiring edge plating before through-hole plating to avoid damage during V-cutting.

Clearly mark areas that require edge plating in the mechanical layer before fabrication.

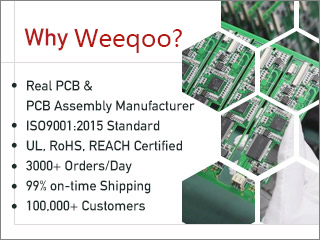

Reliable Edge Plating Services at Weeqoo

Edge plating helps strengthen PCB connections and reduces the risk of device failure. Because of its stability and versatility, it’s now widely adopted in PCB manufacturing for applications that need robust electrical and mechanical connections.

Weeqoo is equipped with professional tools and experienced engineers to perform precise side plating. For more details about our edge plating process or design requirements, please contact us via email or reach out through our online support.