What is Metal Core PCB?

Metal Core PCBs, or MCPCBs, utilize a metal substrate as opposed to the standard fiberglass substrate. The most widely used substrate materials are aluminum, copper, and steel alloy. Among them, aluminum-based PCBs are the lowest in cost — they offer good heat conductivity and dissipation at a lower rate. Copper-based PCBs have better heat conductivity but at a greater cost, and steel-based ones are more rigid but poorer in heat conduction. Because of their high thermal capability, metal core PCBs are in great demand in those applications where heat needs to be managed.

As modern electronics move towards miniaturization, lower weight, higher functionality, and more performance, managing heat is turning into a daunting task. Excessive heat can easily affect the dependability and stability of the circuits.

Metal core PCBs provide a cost-effective solution to these thermal issues, especially for high-density circuit layout, whether for volume production or prototyping.

Key Advantages of Metal Core PCBs

1. Better Heat Dissipation

The most significant advantage of metal core PCBs is that they have good thermal conductivity. Compared to standard FR4 or CEM3 boards, copper and aluminum PCBs conduct heat much more effectively. These good heat conducts minimize damage to electronic components, increase the product life, and provide good operation under load without any issues.

2. Excellent Dimensional Stability

Both copper and aluminum PCBs possess a higher coefficient of thermal expansion (CTE) when compared to FR4 boards. Higher CTE means that the board can better handle temperature changes without deforming, offering structural integrity even with excessive heat.

3. Less Distortion

As metal core boards are efficient in dissipating heat, these boards will undergo less warping or distorting during temperature fluctuations during signal passing or device operation.

Applications of Metal Core PCBs

These advantages render metal core PCBs appropriate for the following applications:

Power converters

LED lighting and backlight modules

Photovoltaic devices

Automotive lighting

Home appliances

Among them, PCBs based on aluminum are used most extensively due to an equilibrium between cost and performance. Within solid-state lighting, for instance, aluminum PCBs allow more brightness using fewer LEDs.

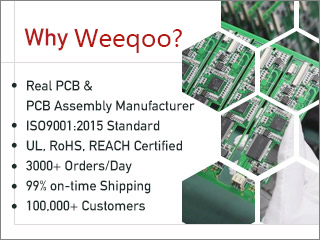

Weeqoo's Metal Core PCB Capabilities

We can manufacture metal core PCBs with copper foil thicknesses ranging from 1oz to 10oz and metal core thicknesses of 30mil to 125mil in Weeqoo.

If your application requires custom thicknesses or specialty substrates, our engineers are available to assist with custom solutions.

Weeqoo updates its equipment and techniques regularly to keep up with the latest industry advancements — so every customer has reliable support for PCB prototyping, manufacturing, and parts procurement.